the art of block printing

the process

rutland x jaipur

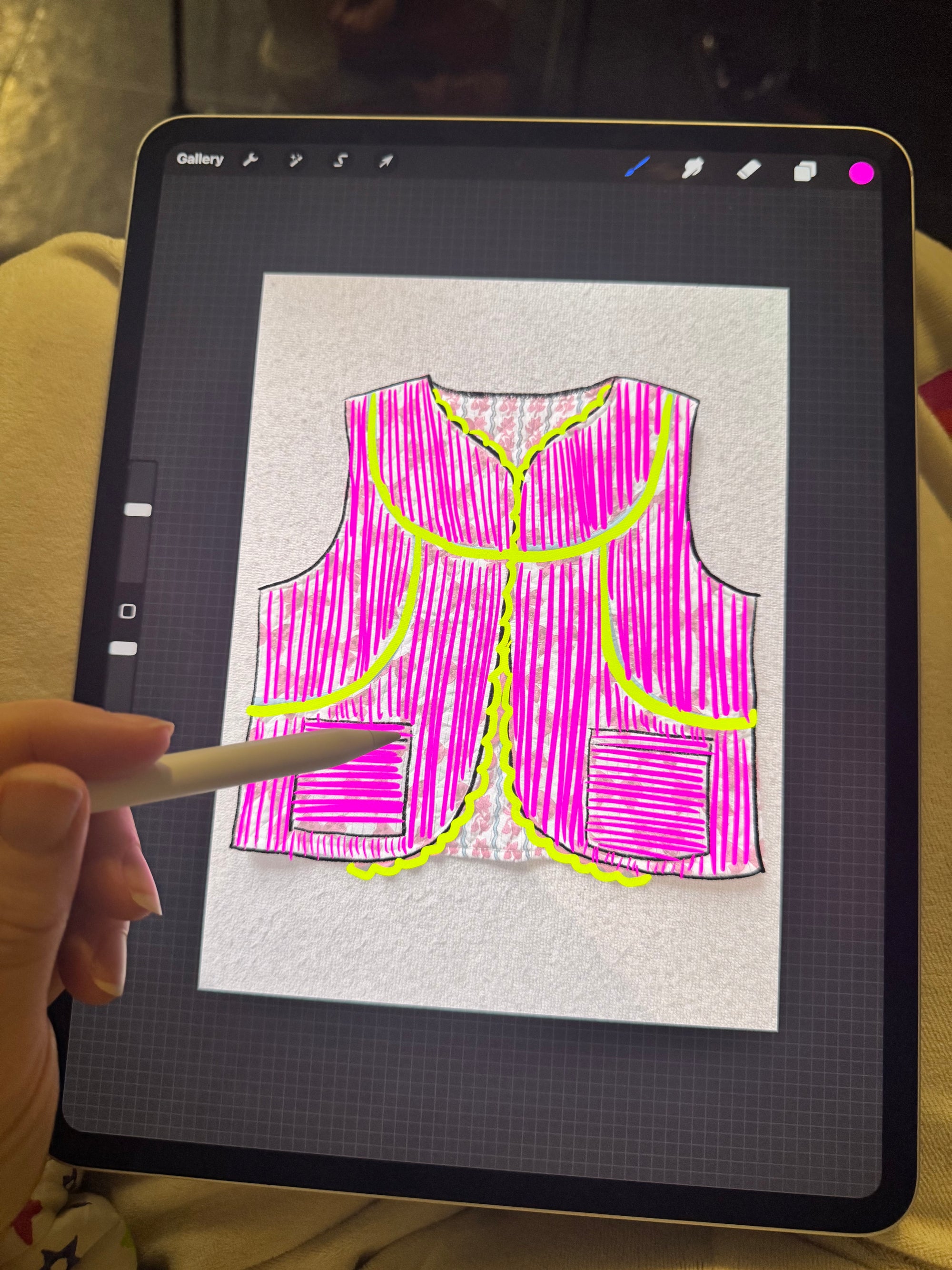

All of our Bombaby prints start out as a whimsical, colourful idea floating around my slightly bonkers brain. I'm always scribbling down ideas and sketching designs on scraps of paper

Once we have the final design down on paper, here in leafy Rutland, our artisan team in Jaipur then brings the print to life with the fascinating technique of block printing.

the blocks

Before the artisans can start printing, the design must be carved into each block. Each colour has a different block, so it is highly important to get the exact design in your hand. The block-carving artisans make use of tools such as small hammers, chisels and drills to be able to carve elaborate patterns (which later form our Bombaby prints) into wooden blocks.

After the carving process, these blocks are dipped in mustard oil and allowed to rest for at least a week. The carvers also drill miniature holes into the wooden blocks to allow the wood to breathe. This also extends the life of a wooden block by up to a few decades, which reduces waste.

the printing

Next, the craftsman will lay the fabric on a printing table, stretching it across the entire length and holding it in place with tiny pins.

Block printing has a special technique that needs to be followed in order to get the desired results and create beautiful bright Bombaby prints. Printing always begins from left to right and a plank of wood is used to even out the colour on the tray. The craftsman dips the block into a dark outline colour and applies it to the fabric. This is done repeatedly along the length and breadth of the fabric and it is this hand-printing technique that makes every piece of fabric and every Bombaby product slightly different.

stitch by stitch

Once the fabric is ready for printing, it moves to the stitching unit where it will be quilted (filled with organic cotton) and carefully stitched by our skilled team into the Bombaby items you know and love.

The process is slow; we also don't like to burden our artisan team and so only order in small, made-to-order batches. Scraps and surplus materials are keenly used for trims and linings; no two products are ever the same.

Everything is slowly handmade for busy living.

always neon

Traditionally, block printed fabrics are made in more natural earthy tones.

Although we use traditional block printing methods, our neon prints are anything but traditional.

We love pushing the limits with the colours we use, although our dyes are always azo (chemical) free and safe on delicate skin.